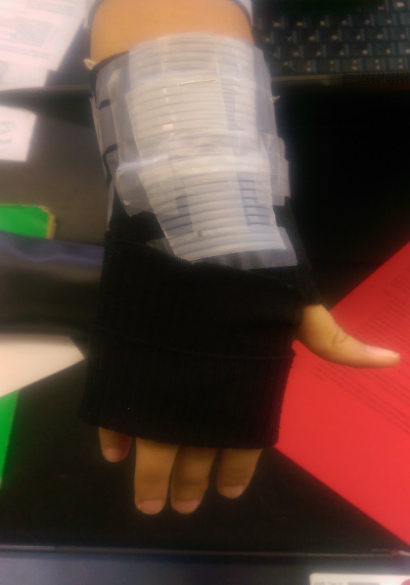

Our team Titans have made really good progress this far in the project, and our main mission right now is to create a working prototype. Now of course our team has come to the conclusion that the first prototype will not be perfect in every customer need, so we have decided as a group to focus on two main aspects; comfort and joint protection. Building up from these two aspects of our customer needs we hope to soon test our prototype and then slowly add more customer needs into our process of building a new prototype. Currently our prototype is made from a black sock, an extra sew in pocket, staples, cut plastic cups, tape, and an elastic band. The structure of our prototype consists of a smaller hole for people’s thumbs to go through, a larger whole for the rest of your fingers to go through, and the main hole which is where you slide your whole hand through. The prototype is 7 1/2 inches (18 1/2 centimeters) and 3 1/2 inches (9 centimeters. The prototype is stretchy to allow a wide range of sizes to be able to fit the device. Our main source of connecting all the following materials was staples, simply because it was available, but also a steady and reliable material provided.

We created our prototype by first measuring Brianna’s hand with the sew in pocket, and then soon adding a sock over the base (sew in pocket). We were of course able to bind these two by staples and very small amounts of tape. Our next initial step was to cut up plastic cups into small rectangular shapes adding them on the top and bottom of the brace. These rectangular squares were added by excessive amounts of tape, bonded together replicating the rolly polly affect. We decided to incorporate the rolly polly effect because it would insure joint protection helping provided the customer with mobility while their wrist is getting better, as well as the locking system it provides. Each individual squares locks together but also is not bulky. We hope to create this effect in a way where it helps do the job of mobility, but also does not bother the user with their day to day activities. Padding needs to be included in our device and we will develop ideas on how to include the padding as we get farther in our design process. During this particular time, our Biomedical Innovations class was privileged enough to be able to take a trip to the store next door to us called Hancock Fabrics and obtained more ideas about the types of material we will incorporate in our device. Upon various research on padding material we found that the most effective padding material was black rubber foam specifically, neoprene rubber and foam.

I really enjoyed your blog post! I like how you began with discussing your two main customer needs; this shows what you are really focused on as a group and it made it easy to understand how you plan to continue your design process. Your description of your design process was really thorough and I got a clear visual as to what types of materials you used and how each fabric had a specific purpose for your customer. I also liked how you referenced our trip to the fabric store, this shows that you were actively referencing materials we’ve learned about to find the best possible material for your device. Great job! – Krysta H. (The Knee Team)